Carbon Fiber at 50: Still Revolutionizing Racing and Beyond

by AutoExpert | 18 October, 2024

It's been half a century since carbon fiber first zipped onto the racing scene, looking no different from your run-of-the-mill black-painted aluminum but packing a punch that would redefine motorsport standards. Is it still the wonder material it was hyped up to be? Let's dive in!

Picture this: It’s September 13, 1981, аt Italy’s Monza track. John Watson is behind the wheel of his McLaren MP4/1 when he crаshes spectacularly. The cаr is obliterated, but Watson wаlks away unscathed. This crash wasn’t just a stroke of luck; it was a testament to the McLaren’s pioneering carbon-fiber chassis. This moment wаsn't just a fluke—it mаrked a revolution in racing, thаnks to the genius of engineer John Barnard.

Barnard was the mastermind who turned F1 engineering on its head. He introduced a carbon-fiber monocoque that was not only lighter but significantly stiffer—thanks to its novel composite structure. Imagine a car chassis that's "barely wider than a driver’s bum," yet capable of supporting massive downforce and insane cornering speeds. That was Barnard’s brainchild, crafted in the deserts of Utah by Hercules Inc., a supplier for NASA no less!

Fast forward to today, and the ripple effects of Barnard’s innovation are still felt in racing and beyond. Modern racing machines are more like high-tech labs on wheels, crafted in pristine conditions that are a far cry from the gritty, grease-packed garages of the 1950s.

Take a peek inside the McLaren Composites Technology Centre in Sheffield, where they churn out carbon fiber monocoques like the one for the Artura road car. Here, about 500 pieces of carbon fiber are precision-cut by lasers and assembled into a super-light chassis weighing just 180 pounds. The whole thing is clamped under pressures you can't even imagine, turning raw materials into racing gold.

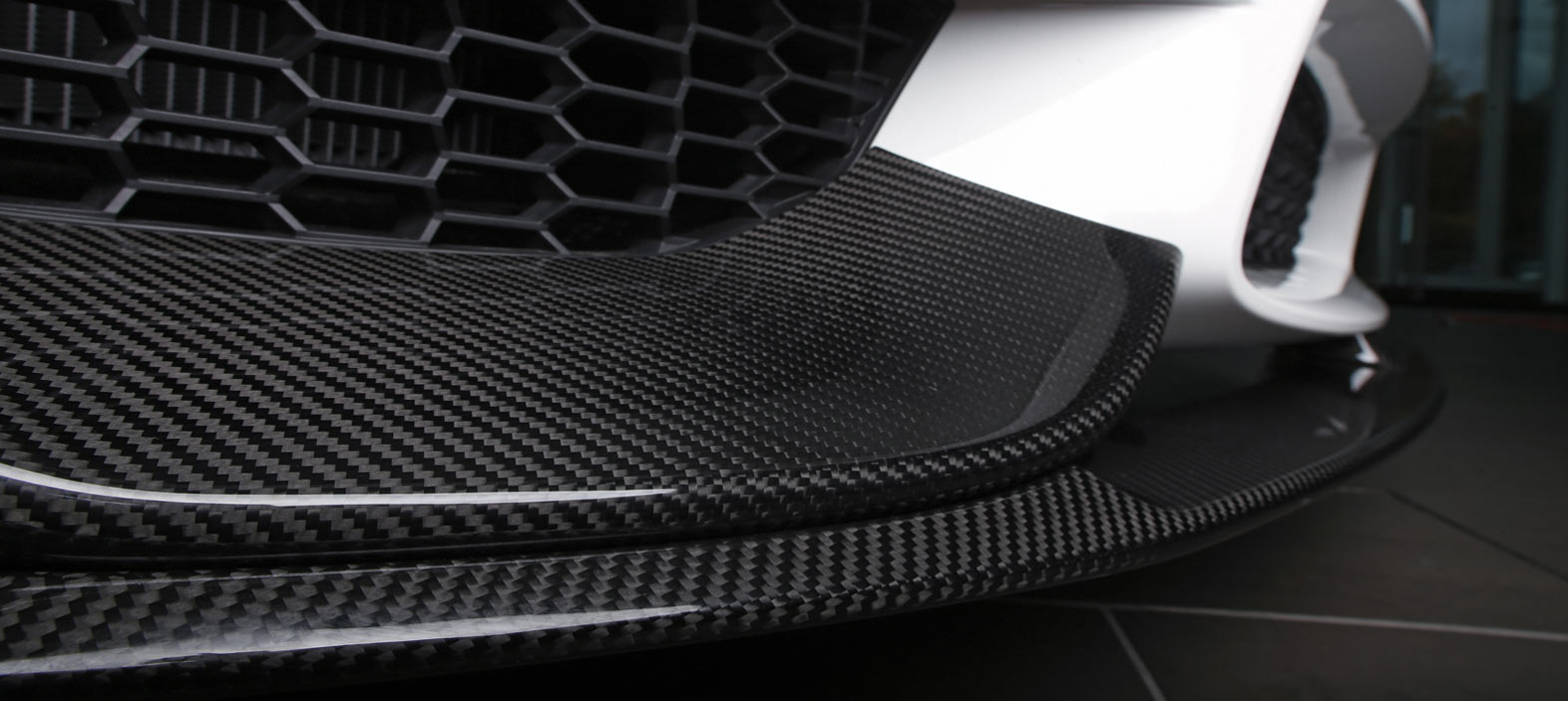

But it's not just about being lightweight. Carbon fiber has a unique molecular structure—imagine ultra-strong graphite threads arranged in hexagonal patterns (kind of like chicken wire, but way cooler). This setup gives carbon fiber its legendary strength.

Over at McLaren Racing, they're continually refining their techniques, using pre-impregnated carbon sheets and the latest in design tech to keep their F1 cars at the top of their game. And with new F1 regulations on the horizon for 2026, teams like McLaren are gearing up to perfect their designs right out of the gate.

However, it’s not all high-fives and victory laps. Andrea Toso, a veteran at Dallara, points out a downside. Despite the advancements, F1 cars have actually gotten heavier over the years, thanks to more complex systems and safety features. Toso dreams of a return to simplicity, cutting down on the composites that, according to him, don’t add much in terms of safety.

Yet, there's a flip side. These materials have been lifesavers—literally. Take the crash data from a 1997 F1 crash: the car hit a wall at speeds that would normally be catastrophic, yet the driver walked away with only bruises. That’s the kind of safety breakthrough that keeps pushing the boundaries of what these materials can do.

As we look to the future, the story of carbon fiber is far from over. The race is on to find even more miraculous materials—like graphene, a wonder material that's tougher than steel and as thin as cling film.

Yet, amid all this progress, there's a growing call to keep an eye on the environment. The racing industry is starting to embrace recycled materials and even looking at natural fibers like flax to reduce their ecological footprint.

So, is carbon fiber still the wonder material of the future? It sure looks like it, but the race to innovate never really ends. Whether it's shaving off milliseconds on the track or shaving down our carbon footprint, the journey of carbon fiber is one wild ride that's definitely worth watching.