Revving Up Production: A Look into the Car Factories of the Future

by AutoExpert | 5 October, 2023

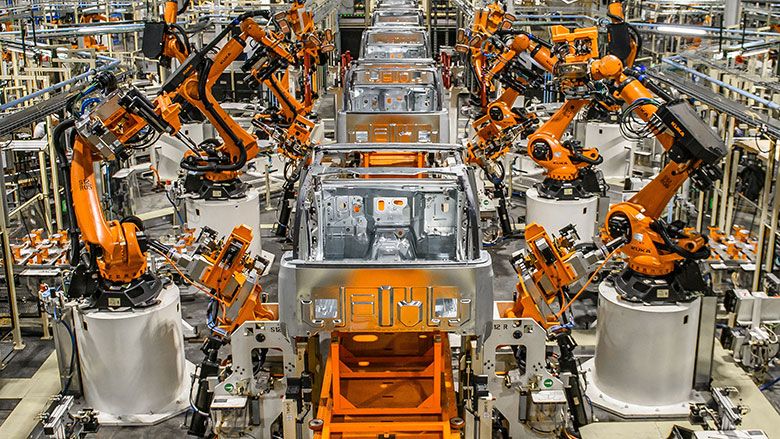

The hum of machinery, the dance of robots alongside human engineers, the birth of sleek, efficient vehicles ready to tackle the roads - the car factories of today are evolving into a realm where innovation drives every bolt, weld, and spray of paint. As we venture into the domain of the automotive future, the transformation is both astonishing and inspiring. Car factories are becoming hotbeds of technological advancements, embracing a symphony of automation, sustainability, and efficiency. Let's take a drive through the modern marvels shaping the car factories of the future.

Accelerated Production:

The race to speed up production without compromising quality is a hallmark of the future car factory. A shining example is Volkswagen, setting a bold target to reduce the production time of their electric models to 10 hours, a steep descent from the current 30 hours taken to build the ID 3.

Robotic Renaissance:

Robots are no longer confined to repetitive tasks; they're evolving into collaborative partners. With enhanced sensors and machine learning capabilities, robots work alongside humans to enhance precision, speed, and safety.

Sustainable Symphony:

The future car factory resonates with the tune of sustainability. From harnessing solar and wind energy to power operations, to recycling and reusing materials, the eco-conscious ethos is deeply ingrained in the production narrative.

3D Printing Prodigy:

3D printing is not just a novelty; it's a game-changer in car manufacturing. It enables rapid prototyping, customizations, and even on-site production of spare parts, reducing lead times and waste.

Smart Factories:

The factories are getting smarter with real-time data monitoring, predictive maintenance, and adaptive production lines. These smart factories respond swiftly to changes, ensuring optimal performance and minimal downtime.

Virtual Reality (VR) and Augmented Reality (AR):

VR and AR are opening new dimensions in design, training, and troubleshooting. They provide a virtual playground to test designs, improve processes, and enhance the skills of the workforce.

Cyber-Physical Systems:

The fusion of digital twins with physical operations is creating a seamless loop of monitoring, analysis, and improvement, bridging the virtual and real worlds of car manufacturing.

As we cruise through the unfolding narrative of car factories, the future seems to be a blend of efficiency, innovation, and responsibility. The road ahead is thrilling, and we're here for the ride, eager to witness how these advancements will reshape the automotive landscape, making it more agile, sustainable, and human-centric.